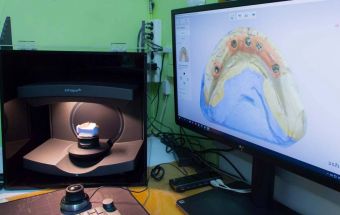

CAD/CAM Technology

Dental prosthetics

Digital technology is inextricably linked to the methods we use for excellent results in cosmetic dentistry. The design and construction of computer aided all-ceramic zirconia restorations (Computer Aided Design and Computer Aided Manufacturing – CAD/CAM) is the most advanced method that guarantees accuracy of application and biocompatibility. The use of CAD/CAM technology is suitable for bridges and crowns, implant restorations, telescopic crowns, abutments, Maryland bridges and precision connectors.

With the specialization of our team in the use of digital technology we hold a leading position in the services we offer throughout Crete, and with the guaranteed results being the best proof of our work we stand out in modern dental technology. Our lab covers the full range of dental prosthetics and implants, allied with the 7series and 3shape E3 digital scanners with the respective design programs, ensuring excellent results.

The construction of molds for fixed prostheses, splints, base plate custom trays as well as the construction of temporary bridges and crowns is carried out with the Rapidshape and Formlabs 3D printers, while the imes-icore 250i and imes-icore 4820 milling machines ensure the absolute innovation in our work. They are a 5-axis milling machine certified for dry or wet milling of lithium disilicate and zirconia and a 4-axis machine certified for dry or wet zirconia and metal milling, respectively.